J-Paver screed can be hydraulically extended from 2.3 to 6.0 meters, without any mechanical extension to add.

With this syspem you can save up to 50% work of time.

Even during paving, the paver extension can be changed without having to stop the process to install or uninstall any extension. The screed, well designed, not needing any auxiliary extension, give pavement quality good (surface finish, density), and not caused problems, of any difference, between the central and additional hydraulic extension.

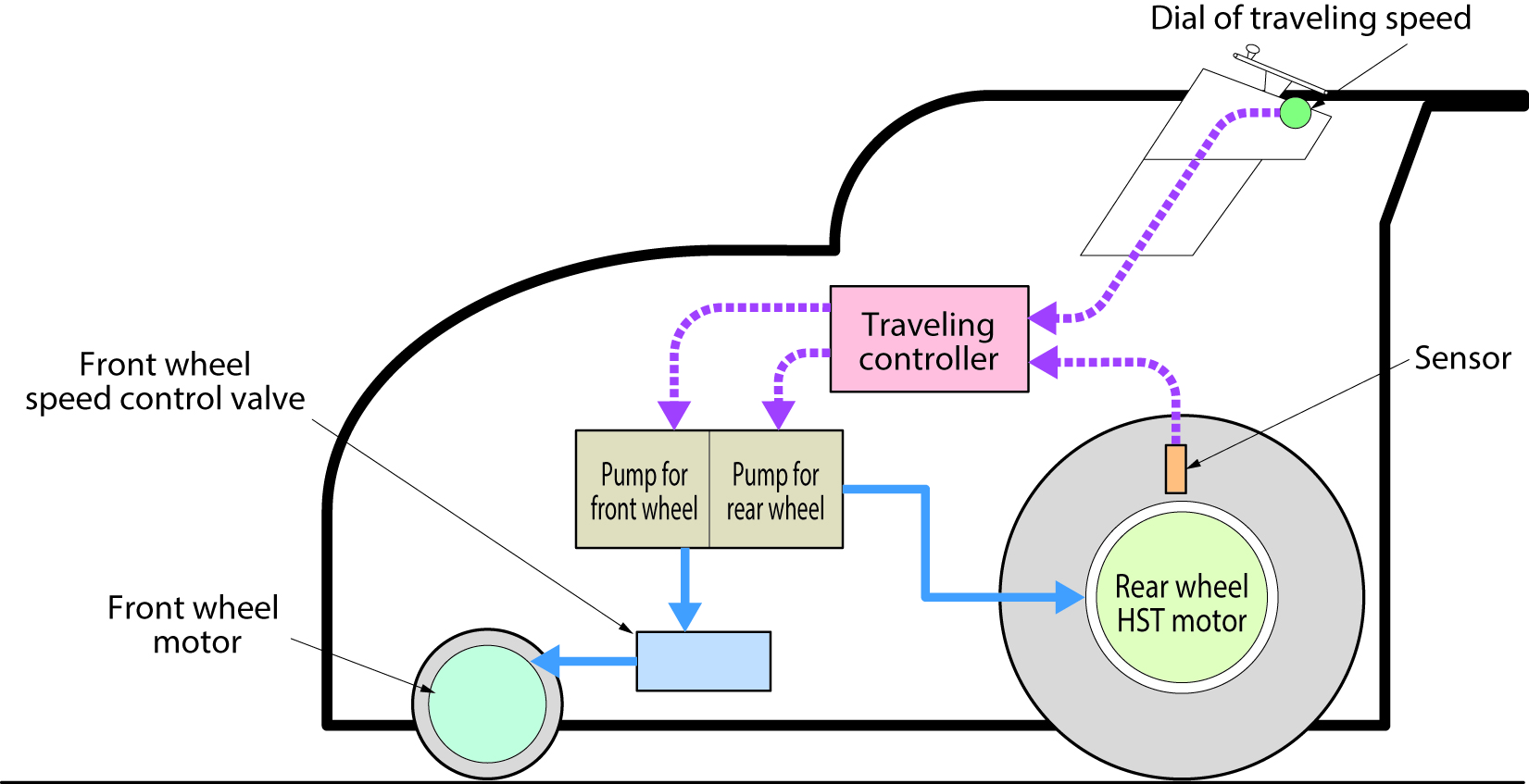

Sumitomo Strike-off

The innovative system, called STRIKE-OFF (installed in front of the tamper), provides a flow of optimal material and a precompaction of the material, before arriving under the TAMPER giving total support in all conditions of pave.

Adjustable Height hydraulic extensions

The J-Paver screeds allows an easy adjustment of the height of the hydraulic extension through simple switches. Thanks to this device, when there is a gap between Central Screed and extensions (left or right) can be adjusted immediately quickly without using any tool or key.

Gas screed Automatic temperature control

The heating temperature setting, of J-Paver screeds, is automatically controlled throw a display. Moreover, in the case where a turned off accidentally the flame, the gas supply is automatically excluded and a light swith on to give the alarm.

Tamper and vibrator speed control system

There are, by the display, the electronically controlled to check tamper and vibrator RPM; thanks a series rpm counter, is allowed to read in the display the revolutions in real time. You can varied both from the main panel or from the panels installed on the ground (by screed operators).

YANMAR-4TN107 Engine (Single turbo + Intercooler)

The propulsion system, a combination of YANMAR’s intelligent new engine concept and SUMITOMO’s state-of-the-art technology, offers high work efficiency and low fuel consumption. YANMAR-4TN107 meets EU Stage V emission standards.

![4TN107FHTFRONT02[1]](https://www.omsbressan.com/wp-content/uploads/2020/04/4TN107FHTFRONT021.jpg)

Rear wheels transmission

Rear transmission uses a “HST Direct Drive” installed inside the gearbox left and right. The system is designed to elimination the chain of reference, this means that the hydraulic transmission of motion is done directly, through the gear reducer, to the wheel without to use of drive chains, thus eliminating the problem of replacing or breakages.

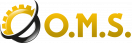

A computer controls the engine, hydraulic pumps, and hydraulic motors. In addition, the settings are stored, so the paving can be performed by simply switch. The controller HA60 W-8 contains the following special features:

- The speed variations, due to changes in the load weight, do not occur, so as to improve the coating of the bitumen in every condition.

- The paving speed can be set from a minimum of 1 m / min and adapt to all types of work.

- At the start of the paver, a control function is used to obtain a soft-start.

- The paving speed can be varied at any time always giving maximum results of yield.

Hopper managed separately

The hoppers, left and right, are able to move independently up and down; at the same time also the front hopper, (that move up and down), moves automatically. Thanks to the conformation of the hopper and the tires installation, in many cases there is no leakage of material in front of the push rollers and the machine.

Moreover, thanks to the careful study of the design, the front of the hopper is lower than other machines favouring the access of the trucks, without touching the hoppers frame anywhere, or break the protection tires install in front of the hopper.

Hydraulic Auger

Two hydraulic cylinders move up and down the augers frame, thus favouring the regular supply of the material according to the thickness and greater precision during the various and different processes to use the paver.

Mold-board

Thanks to the extension and retraction Mold-board, ( installed in front of the extension having a function change the flow material) the materials are conveyed efficiently from the auger, so there is an effort reduction of the machine, as well as an improvement in the paving precise. These tools are also equipped with two hydraulic cylinders to purpose of calibrating the flow in front of the extension.

Auger and conveyor reversible

To obtain a good balance of material in front of the screed, the paver is equipped with a reverse a augers and conveyor rotation, completely separated, that distribute the asphalt evenly, allowing to finish paving with a minimum of material in front of the screed, or move the machine without losing material during the move.

Roller thrust oscillating

Push the truck while paving is facilitated by oscillating push rollers. These help steering the machine in every manoeuvre without having to remove the truck.

External control panels

The extension/retraction extension, the control of the thickness, the call/suspension of the material, or the auger reversing and a button to sound the horn are functions possible by external control panels, where a display, also, allows the variation of revolutions tamper and vibrantion, as well as setting and controlling the temperature of the screed. Furthermore, they have also an emergency stop switch.

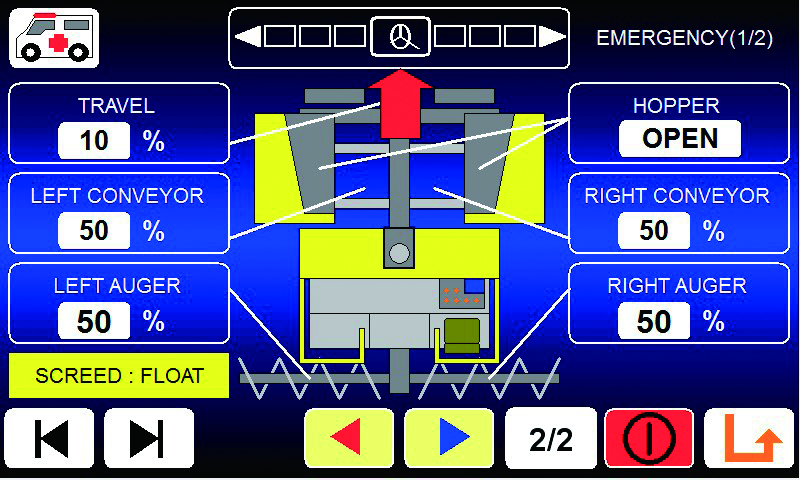

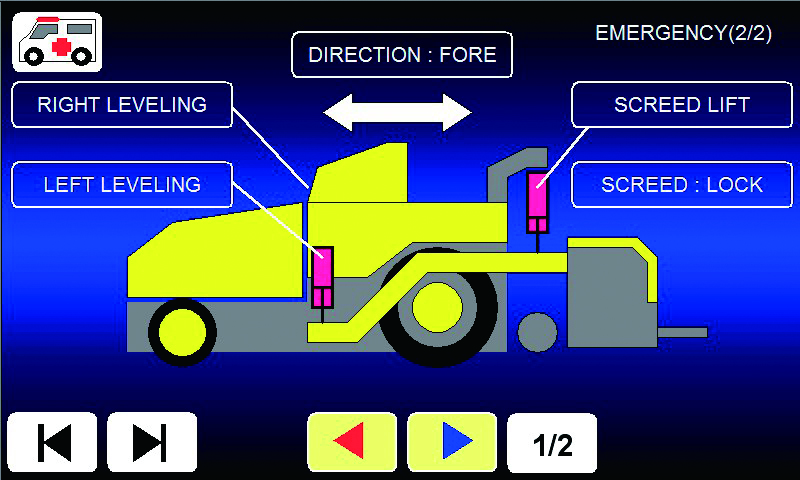

Function of emergency

In a worst case, where there was a computer or an engine problem, the paver is equipped with VARIOUS emergency mode to end the paving or move the HA60W-11 from the front paving line.

LCD Colour panel

The machine is equipped with a colour liquid crystal panel. In this panel the functions are schematised and allow easy understanding. Passing from first to second gear, the reading scale is adapted from m / 1 to Km / h so as to be more understandable to read; also there is a graphic system to understand the steering position in 7 different square, which allows to inform the operator, the steering degree. The main control panel is also translatable by both sides, so as to facilitate the operator in every driving situation. It is also possible to install a camera in the front of the machine, displayed in the display, to be able to view the amount of material inside the hoppers.

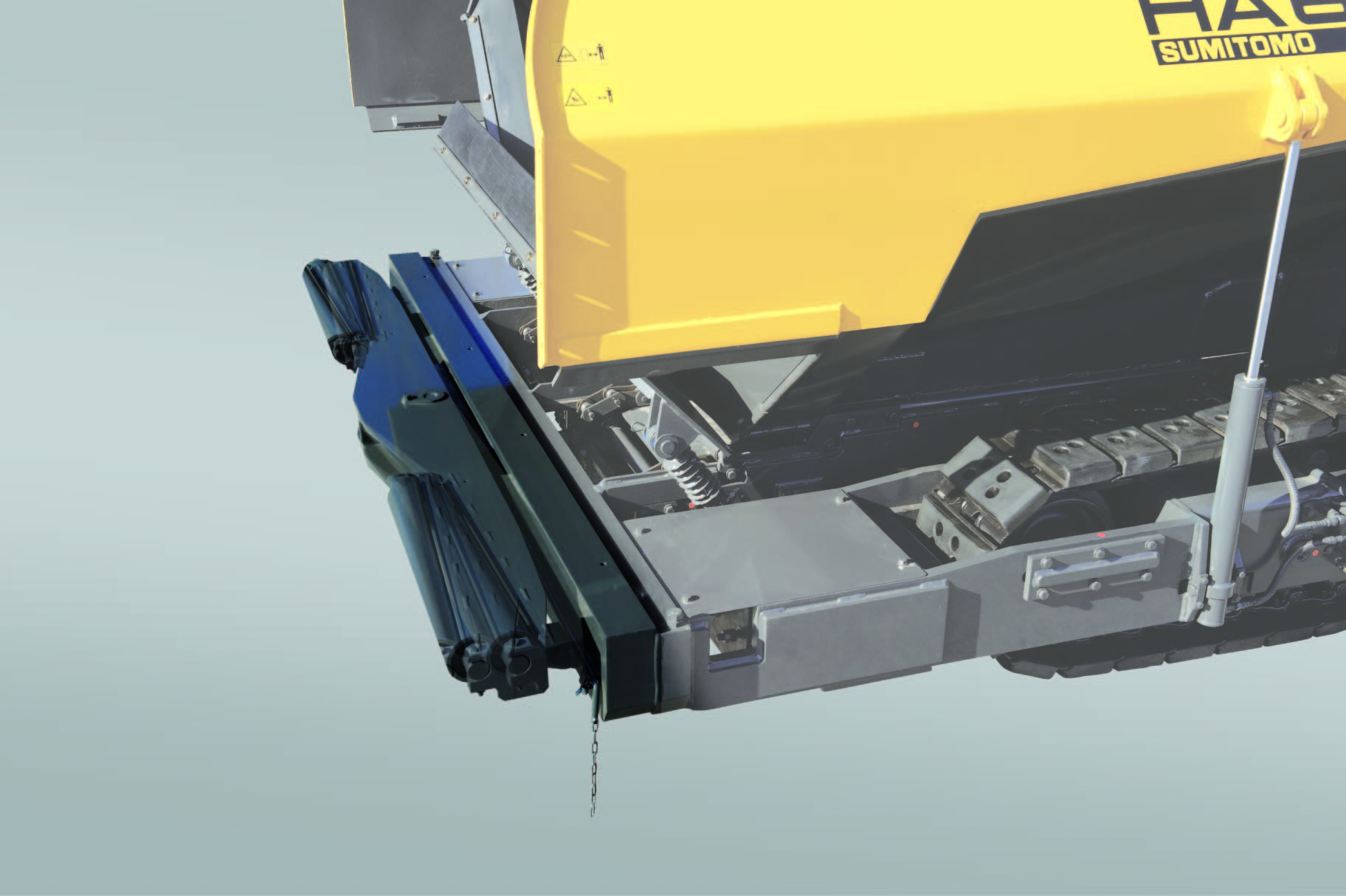

Functions lock and automatic soft-start

When the paving operations are temporarily suspended, waiting for the material or otherwise, the automatic locking device is activated, to prevent to go into the material the screed. When we restart to paving, the soft-start function, controlled by the computer, is automatically activated and the machine can move forward without leaving marks on the surface material.

Compact Package

The screed width and the conformation of the roof are, in the HA60W-11, allow to easily fit the machine in the truck in because, width limit of 2.5 m and a height of 3.0 m, are important rule for the transport.

| TECHNICAL INFORMATION | |

|---|---|

| MACHINE TYPE | PAVER |

| BRAND | SUMITOMO |

| MODEL | HA60 W-11 |

| YEAR | |

| PLATE | |

| SERIAL NUMBER | |

| WORKING HOUR | |

| ENGINE | YANMAR-4TN107 (EU Stage V) |

| WEIGHT | 15900 KG |

| DIMENSION | 2,490 x 6,590 m |

| MAX WIDHT | 2,3 x 6,0 m |

| TRANSMISSION | WHEEL |